Bunsen Burner Testing

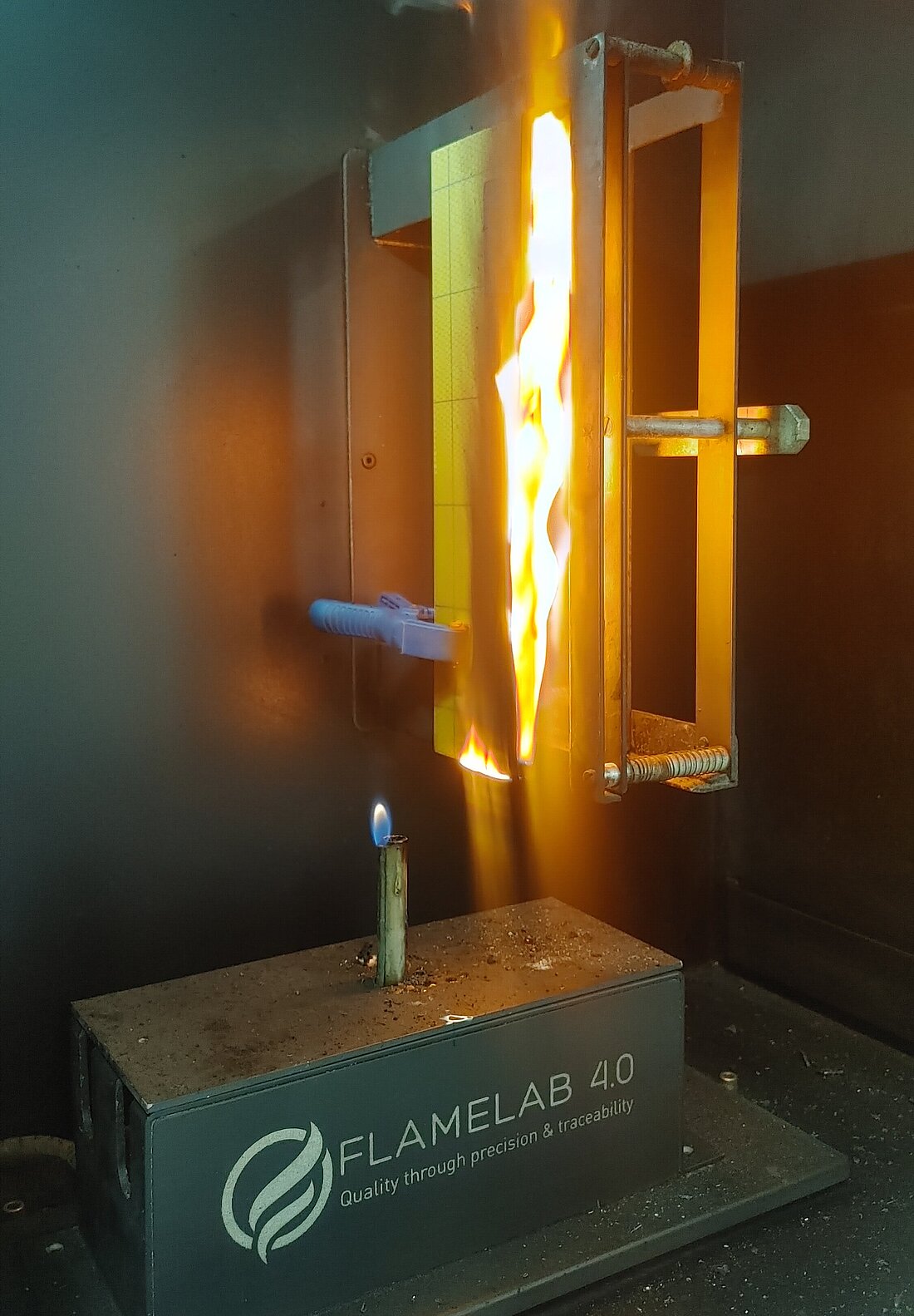

QCM Flamelab is home to Flamelab 4.0 (EN9100 certified), the world's only automated fire testing service which measures the flammability and fire resistance of materials to be used in aviation interiors.

By eliminating the human variables introduced through manually-performed testing, Flamelab 4.0 raises productivity and test quality to a higher standard, resulting in reliable, more accurate testing and results.

Our Bunsen Burner tests align with the fire testing requirements stipulated by the FAA in Federal Aviation Regulation (FAR) 25.853 and FAR 25.855, to determine the resistance of materials to flame.

We also offer Oil Burner Testing for Seat Cushions to certify your aircraft seat cushions according to FAR 25.853 App. F Part II.

Benefits of getting your testing done with QCM Flamelab:

☑ max. 26 hour lead time*

☑ fully automated testing, eliminating human factors

☑ 100% repeatability

☑ testing 7 days per week

☑ human factors eliminated

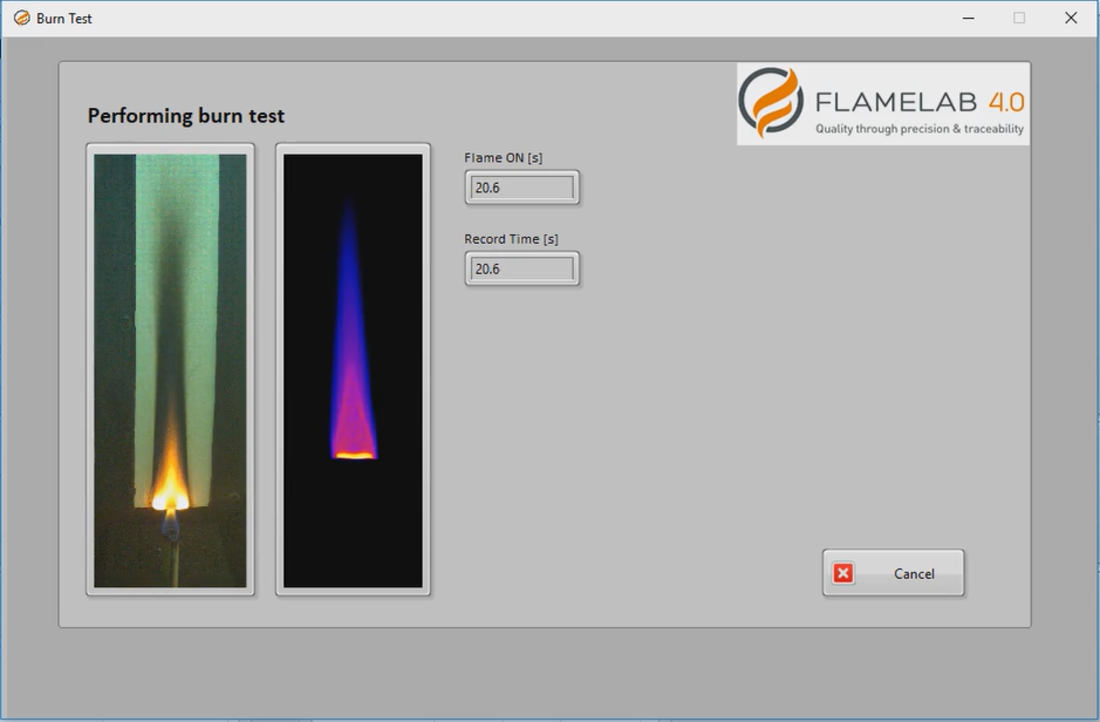

☑ video and thermographic recording of tests

☑ review all sample results & data years after testing, with our specimen traceability

*from when samples are received at the lab. 48 hour lead time from when sample is collected from your facility to receiving results is possible when using priority shipping.

Video and thermographic recordings are done for every test to verify the results. While some labs charge you for these recordings, we include these with all test results, allowing you to review the results firsthand.

For any tests which fail, we also include expert-reviewed recommendations, so that you can more easily address the reason for failure.

Our Process, from Start to Finish

1. Send min. 3x samples (we recommend 4x samples) of each material to be tested to our laboratory in Poland.

2. We assign a QR code to each sample for specimen traceability, allowing you to easily trace results for your samples.

3. We conduct the required tests on all samples provided.

4. Within 26 hours of us receiving your samples, you will receive your test results. This includes either a pass or fail, as well as the video and thermographic image recordings.

- If your test has failed, we will also include recommendations based on the tests.

5. All results and accompanying video and thermographic image recordings are uploaded to a shared folder which you can access at anytime, even years from now.

Find more information on how to order Bunsen Burner tests here.

Capabilities & Areas of Application

Aviation (compliant with EASA & FAA)

We offer fire tests for aircraft materials according to FAR/CS 25:

- 60 Seconds Vertical Test: CS 25.853(a) App. F Part I (a)(1)(i)

- 12 Seconds Vertical Test: CS 25.853(a) App. F Part I (a)(1)(ii)

- 2.5 inch/min Horizontal Test: CS 25.853(a) App. F Part I (a)(1)(iv)

- 4.0 inch/min Horizontal Test: CS 25.853(a) App. F Part I (a)(1)(v)

- 45 degrees Flammability Test: CS 25.853(a) App. F Part I (b)(vi)

- 60 degrees Flammability Test: CS 25.853(a) App. F Part I (b)(vii)

- Fire Containment Test: CS25.853(h) and AC 25-17A

Other Applications:

Our precise and reproducible fire testing capabilities also extend to a range of other industries, including: public transport, automobiles, textile/leather manufacturing, interior design, and yachting & boating.

Automotive

- 4.0 inch/min horizontal: FMVSS 302, CMVSS 302

Railway

- Heat Release Rate: PN-EN 45545-2 / ISO 5660-1

- Smoke Density + Toxicity: PN-EN 45545-2 / ISO 5659

Flamelab 4.0 Benefits

Flamelab 4.0 uses state-of-the-art technologies to raise fire testing to new heights in both quality and productivity terms, with features including:

- Extensive automation

- Precision reproducibility

- Automated documentation of results

Technical specifications

As well as using sophisticated cameras, this specially-developed analysis tool provides both highly precise measurements and excellent analysis options. To these ends it makes use of:

- Thermal cameras from Optris plc

- Optical camera from Basler Inc.

- High-quality gas system components from Swagelok

- LabVIEW based software with a user-friendly interface

Want more information or to request a quote?

Contact us on +48 668 974 717 or by emailing sales@flamelab.ch